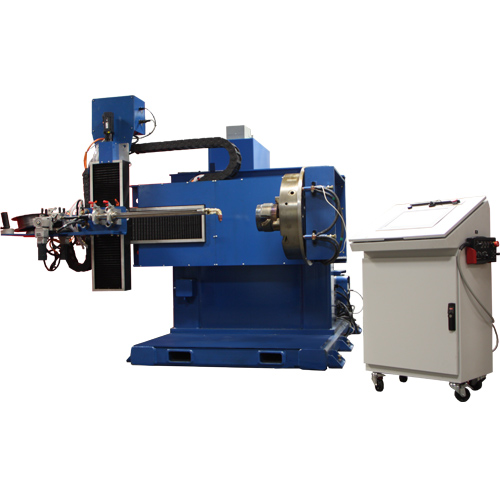

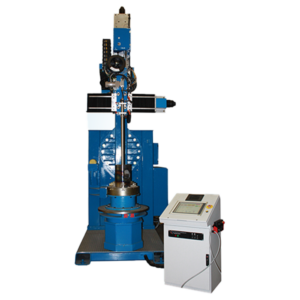

ARC-05HVTE HORIZONTAL, VERTICAL, AND TILT CLADDING SYSTEM

The ARC-05HVT is an automated system capable of welding in horizontal and vertical positions, or at any angle between 0 and 90 degrees on internal and external diameters.

This automated welding system provides better production rates while maintaining a small production area. Optimized deposition rates are available for different applications. ARCSPECIALTIES, along with Arcdynamics in Brazil, can assist in welding procedure qualifications, including the high deposition capabilities available with this machine.

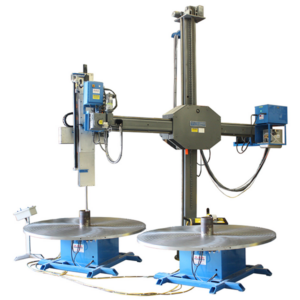

Fully Integrated Robotic Cells Available with GMAW, GTAW, PTAW, SAW, plasma cutting, machine tending, material handling, drilling, and tool-changing options. Cells can be built with one or more robotic arms working together in:

- Conveyor loading

- Conveyor unloading

- Cutting, beveling, coping

- Welding – GTAW, GMAW, PTAW, SAW

- Drilling and tapping

- Safety fences, light curtains

- Additional safety components

This synchronized movement capability helps production units significantly reduce cycle times.

Once integrated, part geometry can be directly input into the control system’s touch screen. This means the software can automatically build programs for the robotic system, requiring minimal robot programming.

All ARCSPECIALTIES custom robotic solutions are designed, built, and integrated with customer specifications in mind.