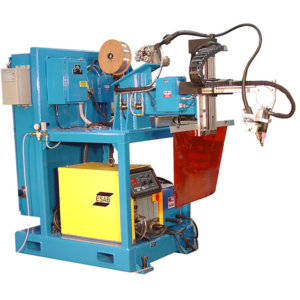

ARC-06S CNC SAW BOP WELDING SYSTEM

The ARC-06S system features a PMAC CNC controller, coordinating the movement of its fully automated 5 axes.

- PMAC CNC controller.

- System with cross-slide mast on a servo linear travel carriage with a linear travel of 120”.

- Integration of tilt and rotation positioner.

- Fully integrated PC-based HMI with feedback of welding parameters, including slide and table position display.

- Remote HMI control.

- Programmable G-code.

- Automated G-code program generation based on part dimensions.

- Automates scratch start to reduce operator intervention.

- Welding with constant surface speed using inverse kinematics.

- Submerged arc welding torch with roll head.

- PowerWave 1000 AC/DC 1000 A power supply.

- Automated flux supply from a 300 lb pressurized flux tank.

- Flux hopper with vacuum recovery (heated flux option available).

More informations in ARCSPECIALTIES website:

https://www.arcspecialties.com/product/arc-06s-cnc-saw-bop-welding-system/

Cateroria Joinning Applications