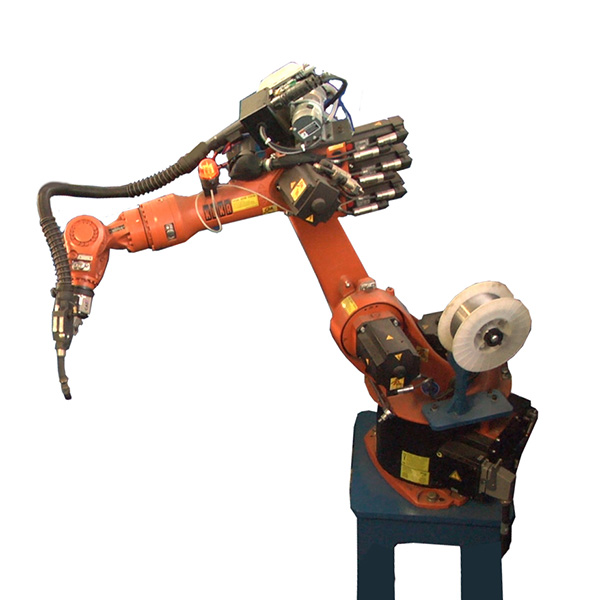

ROBOTIC FLUX CORE WELDING SYSTEM

The Robotic FCAW Welding System is extremely simple. As it indexes the turntable, the robot cuts the wire in preparation for touch sensing.

- It uses the touch sensor to find the weld location on the part.

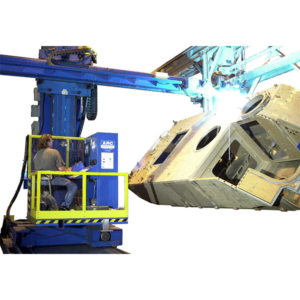

- The operator can safely load and unload parts while the robot welds.

- After a certain number of welds, the torch cleaning station automatically cleans the torch.

- The three-stage torch cleaning station removes weld spatter from the nozzle, cuts the wire to the correct length, and applies anti-spatter inside the nozzle.

- The robot can be lowered to a comfortable working height with the touch of a button for wire or tool changes.

- Due to the skid-mounted design, the machine can be quickly and easily installed and moved to any space as needed.

- Integrated E-stop safety design, as well as a laser detection system that protects the operator.

More informations in ARCSPECIALTIES website:

https://www.arcspecialties.com/product/robotic-flux-core-welding-of-pipe-couplings/

Categorias: Joinning Applications, Robotic Systems